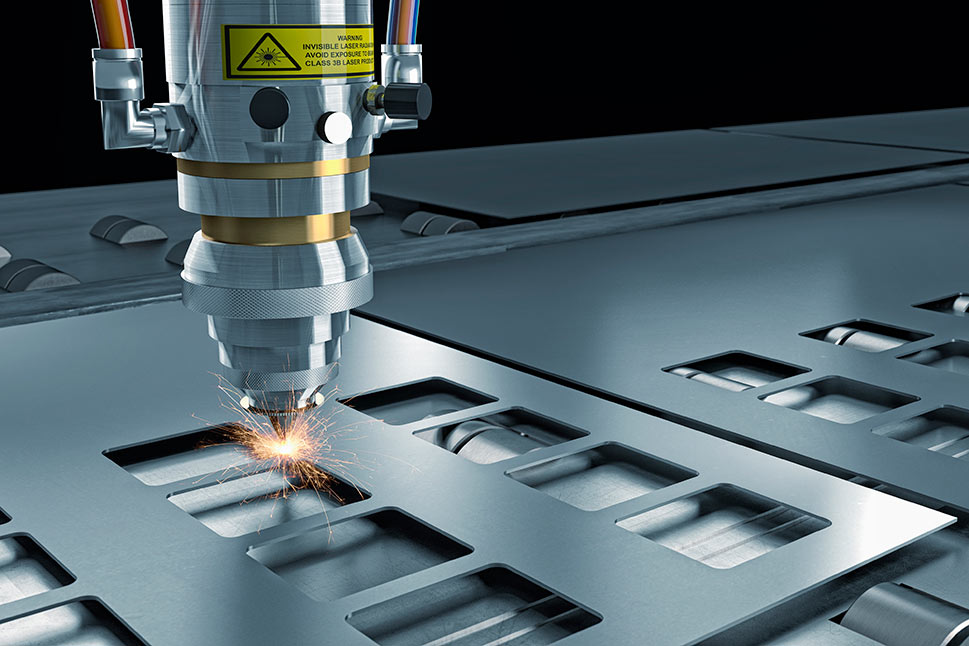

Assist gas

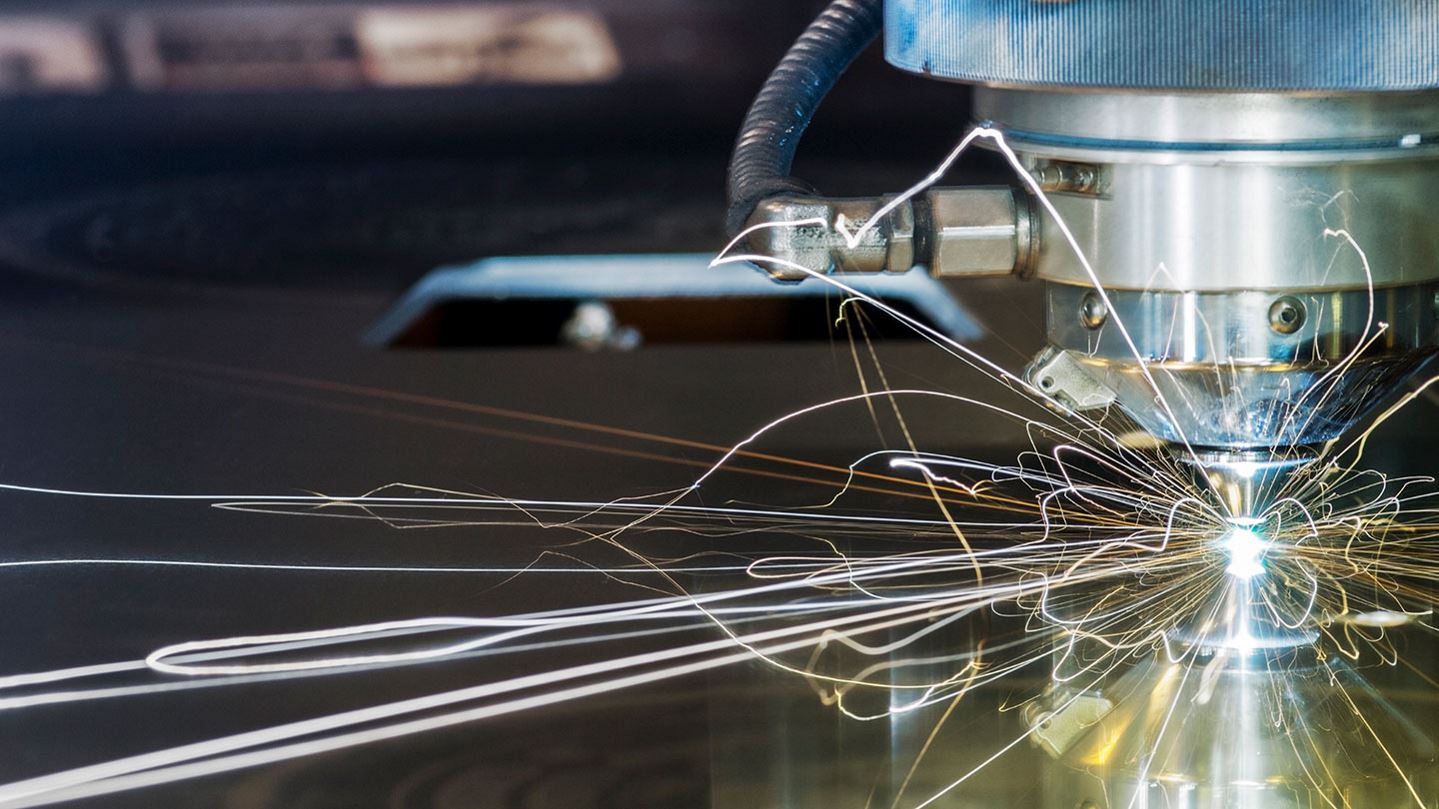

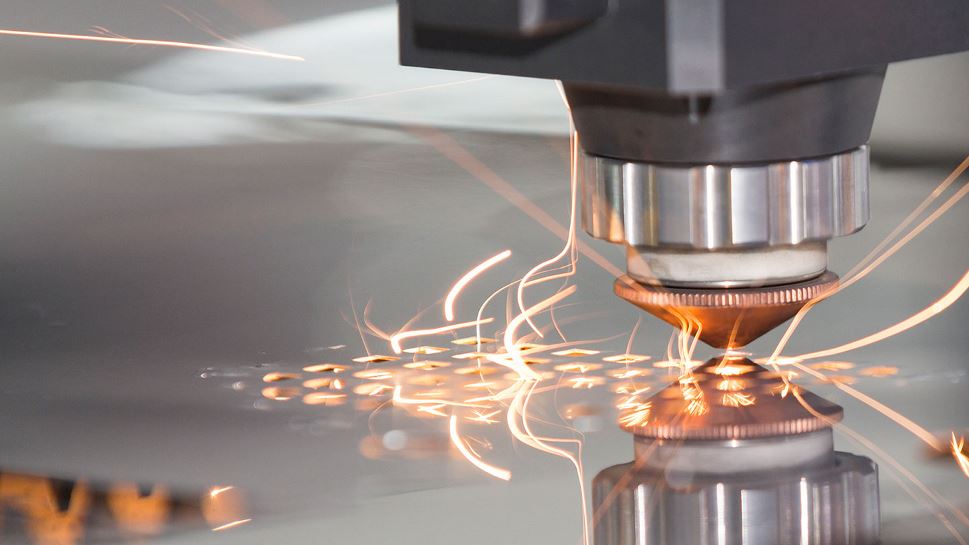

Assist gas is a fundamental requirement of laser cutting and also a key variable in cut quality. The choice of assist gas depends on the material being cut and material thickness.

Flow rate, pressure, nozzle diameter and running time combined with the above parameters, will determine gas usage.

Gas Solutions - you will need assist gas

ASSIST GAS (or cutting gas) is a jet of gas that effectively blows away the molten material to create the cut. A clean cut requires high purity gas. The gas will often need to be delivered at a high pressure and at a set flow rate. These parameters will be determined by your specific laser model.

NITROGEN is used for most cutting applications – in particular stainless steel and aluminium. The material is heated to melting temperature by the laser beam and the nitrogen gas blows out the melt to create the cut and cools to prevent oxidisation. We have market-leading nitrogen supply modes to maximise productivity: the largest capacity cylinder packs in the industry and our high pressure liquid supply which eliminates all downtime when refilling.

OXYGEN is used for cutting unalloyed or low alloyed mild/carbon steels whereby the material is heated to ignition temperature by the laser beam and burned in an oxygen jet. Pressure, the shape of the cutting jet and gas purity determine cut quality and cutting speed. We offer oxygen in various purities and a full range of supply modes to tailor the supply to your specific requirements.