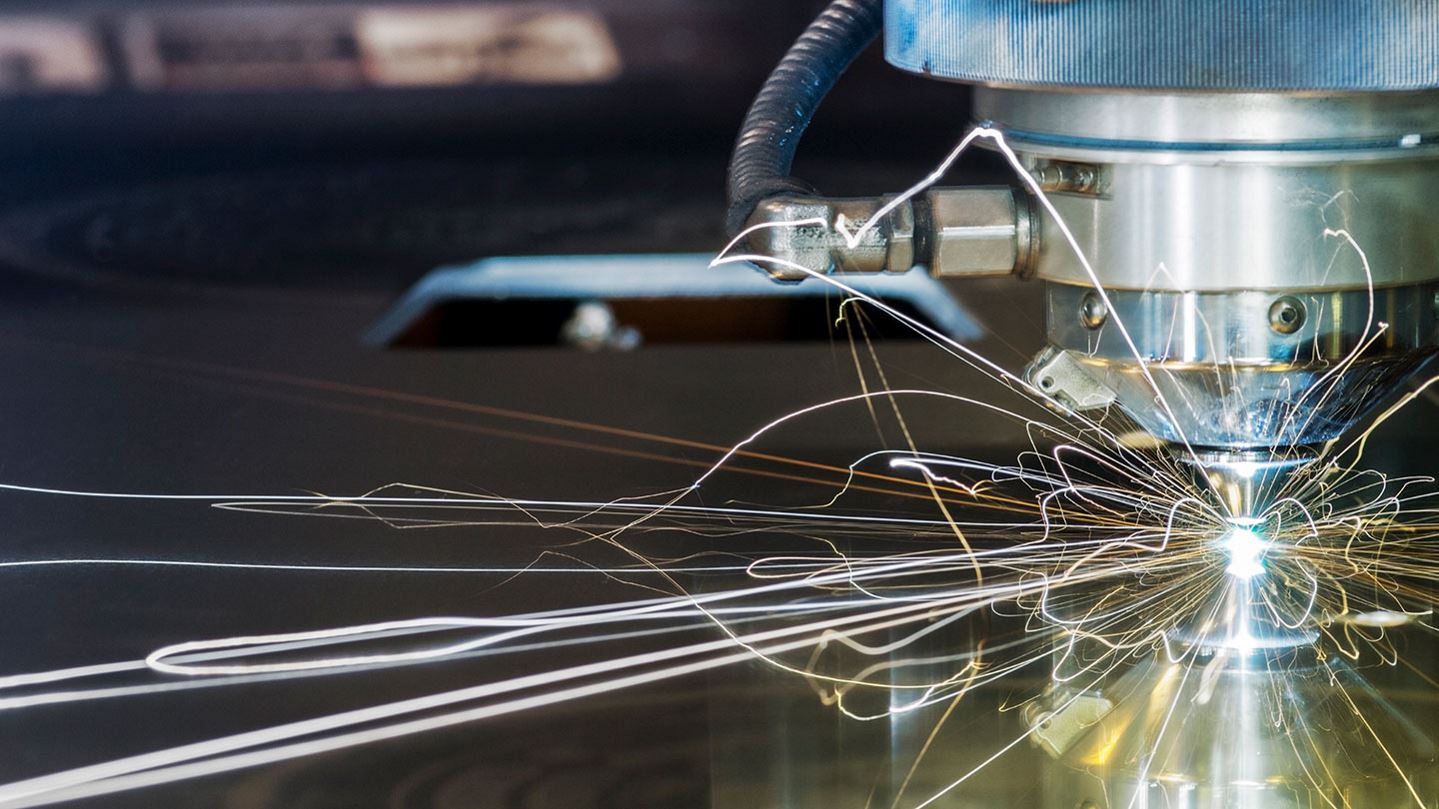

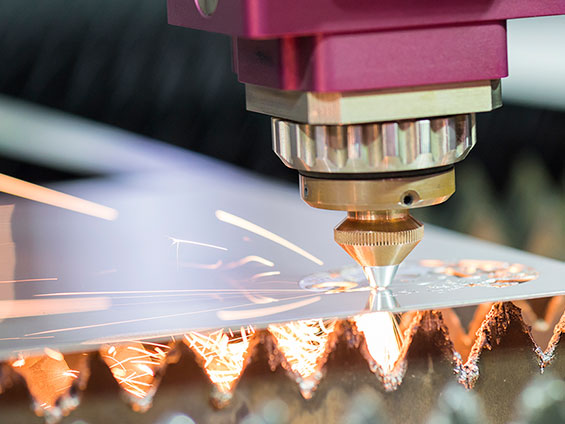

Is your laser gas driving productivity and profitability? Cylinder packs, liquid, gas generation? With so much choice it can be overwhelming. Let us find the solution that works for you.

Overview

At Air Products we have significant experience in working with all sizes of laser customers in a range of industries. We have strong links with many of the leading laser manufacturers and a adopt a long-term fully-integrated approach to ensure that the solution we provide today will drive your business of tomorrow.

Traditional CO2 laser machines require both resonator gas to generate the laser beam as well as assist gas to create the cutting process. The latest fibre laser machines only require assist gas.

For most processes, nitrogen is used as the active assist gas providing a clean unoxidised cut. The key exception to this is thicker carbon steel (8-12mm) which requires the additional heat from the combustion of oxygen assist gas.

How Can I help You?

Does changing supplier sounds like hassle? We making switching simple so that you can benefit from the quality and financial advantages of our laser offer. We have been supplying the laser industry for decades and have successfully transitioned customers of all sizes, locations and footprints efficiently with minimal business interruption.

We can guide you through the process. Which assist gas do you need? What is the best supply mode? How much gas do you need? Do you need resonator gas? Let us guide you through the various considerations.

Gas Solutions

NITROGEN is used for most cutting applications. The material is heated to melting temperature by the laser beam and the nitrogen gas blows out the melt to create the cut. We have leading nitrogen supply modes to maximise productivity: the largest volume cylinder packs on the market and our high pressure liquid supply which eliminates all downtime when refilling.

OXYGEN is used for cutting unalloyed or low alloyed mild/carbon steels whereby the material is heated to ignition temperature by the laser beam and burned in an oxygen jet. Pressure, the shape of the cutting jet and gas purity determine cut quality and cutting speed. We offer oxygen in various purities and a full range of supply modes to tailor the supply to your specific requirements.

SPECIALISED LASING GASES

When it comes to your resonator, purity is critical to ensure optimal laser performance and prevent damage to the optics. We collaborate with the leading laser manufacturers and can supply a complete range of high-purity gases and mixes in pre-mixed cylinders or individual gases.

Supply Modes

CYLINDER PACKS

For smaller laser machines, or smaller operations, cylinder packs are often the ideal supply solution. Equally, for new machine installations, cylinder packs are the initial stop-gap whilst longer-term liquid solutions are sized. We supply 300 bar packs with the largest capacity on the market to maximise productivity and minimise pack changes.

LIQUID SUPPLY

For medium-sized operations we recommend our unique compact on-site high-pressure CryoEase® service. This service allows your gas to be refilled while your laser is still running meaning no loss in vented gas or production time. For larger operations, we have a range of bulk tanks in various pressures and flow rates to suit all businesses. Liquid supply modes remove the requirement to handle cylinders so are safer and more efficient plus, we monitor your tank so there is never a risk of running out of gas.

Gas Installation Services